| Why ventilate? |

Providing the correct amount of air for both combustion and ventilation for appliances is very important. Insufficient air supply can and has led to tragic results and is equally important for gas, oil or solid fuel burning appliances. You should be aware of your legal obligation under the 'Building Regulations' and the 'Gas Safety (installation and use) Regulations 1998' to install the appliance correctly with sufficient air provided.

In principle, the appliance not only burns the fuel but uses the oxygen in the air for combustion. If sufficient fresh air is not provided then the unit will use the available oxygen from the air in the room.

If the air supply to the appliance is inadequate, the flue will fail to clear all of the combustion products and as a result some will spill into the room itself. Ventilating compartments or small closets is therefore particularly important.

When replacement windows and doors have been installed as refurbishment work in a building, ventilation to a room is very much reduced. It is therefore essential to provide the correct amount of free air to appliances.

Other points worth noting are that it is not permitted to fit 'Fly Screens' over vents or airbricks due to the possibility of the screen clogging up and reducing the air flow; nor is it permissible to use a 'Hit and Miss' vent that can be closed, stopping free air supply. If an 'Extractor' fan is fitted in the same room as the appliance extra 50 cm² ventilation per fan will be needed. This also applies to powerful tumble dryers and cooker hoods etc., a spillage test must be confirmed as satisfactory before the appliance is used.

|

|

| Where should you position a ventilator? |

Consider the occupants of a room when installing ventilation. Try to locate the ventilator at high level so the cold draughts will not pass through normally occupied areas of the room. Fitting a 'Black Hole' helps reduce unwanted draughts.

When installing a 'Blackhole' Ventilator it should ideally, be as close to the appliance as possible, but not on the lee side of the building where, under certain conditions, as with all ventilators, air could be sucked out instead of drawn in by the appliance working.

|

|

| What is 'Free Area'? |

'This is the unobstructed cross-sectional area of a grille, louvre or duct, calculated as the sum of the cross-sectional areas of all unobstructed apertures measured through the plane of minimum area and at right angles to the airflow within the apertures' (ref.BS5440-2-2009)

'Free Area' requirements are 5 cm² per kW above 7 kW input. 'Complex' anti-draught ventilators are measured as 'effective free area' i.e. the amount of air which will pass through 'complex' shapes.

|

|

| How do you work out the Free Area for Gas Appliances in rooms? |

British Standard BS5440-2-2009 requires for open flue gas appliances with input ratings exceeding 7 kW to be provided with 5 cm² (5000mm²) of 'Free Area' per kW in excess of 7 kW.

To convert to imperial: 1 kW = 3412 Btu/h |

|

| Can I use a vent with a flyscreen with a Gas Appliance? |

| DEFINITELY NOT – all fixed flyscreen products must NEVER be used for Gas Appliance ventilation. |

|

| Can I use a Hit & Miss ventilator with a Gas Appliance? |

| DEFINITELY NOT – Hit & Miss ventilators must NEVER be used for Gas Appliance ventilation. |

|

| How should air be supplied? |

Ventilation for flueless appliances must always be direct to the outside of the building.

Ventilation for open-flued appliances should be direct to the outside of the building, but may be vented from another room which in turn is vented to the outside. A vent supplying air to an open-flue appliance shall not communicate with a room or internal space containing a bath or shower.

|

|

| How do you ventilate Compartments? |

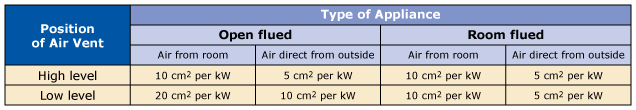

| Where appliances are fitted in compartments, closets or large cupboards, additioinal ventilation of the compartment is required. This applies to both 'Open flued' and 'Room sealed' units. The chart below gives the basic requirements: |

|

Where two or more appliances are installed in the same room or compartment, whether or not they are supplied as a combined unit, the aggregate rated input shall be used to determine the free area.

Please note this information is a guide only. If in doubt refer to current Building Regulations. |

|

| How should appliances be installed? |

Heat producing appliances should be installed so that there is an adequate supply of air to them for combustion and for the efficient working of any flue-pipe or chimney.

Any installation should be installed so that it:

a) receives sufficient air for the proper combustion of the fuel and operation of the flue.

b) is capable of normal operation without the products of combustion becoming a hazard to health.

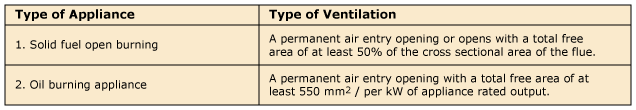

Solid fuel and oil-burning appliances with a rated output up to 45 kW

|

|

|

| What ventilation is recommended for Decorative Fuel Effect Gas Fires? |

BS5871-3 2001 (reviewed 2005): Specification for the installation of gas fires, convector heaters fire/back boilers and decorative fuel effect gas appliances states:

Unless the manufacturer's instructions specifically state the purpose provided ventilation is not required, such ventilatlion shall be provided in the room or internal space containing the appliance. Where purpose provided ventilation is required, tha ir vent free area shall be a minimum of 100 cm², or, where greater, as stated in the manufacturer's instructions.

The air vent shall be either direct to outside air or to an adjacent room or space which itself has a vent direct to outside air of at least the same free area, but not a bath or shower room.

Wherever practicable a direct method of ventilation is preferred.

PLEASE NOTE: This information is just a guide only. Always refer to the current Building Regulations.

|